Which Oral Dosage Form Is Made By Compression

Which Oral Dosage Form Is Made By Compression - This chapter focuses on conventional solid oral dosage forms and is di. Means the physical formulation or medium in which the product is intended, manufactured and made available for use, including but not limited to tablets,. Web release solid oral dosage forms, manufacturing equipment addendum, and (2). Web many solid oral dosage forms are made by direct compression. Tablets may be defined as the solid unit dosage form of. Multiple compression tablet (mct) a tablet formulation on top of. All of the above, the three major broad categories of dosage forms are: Tablets and capsules can be made from powders, granules or from pellets granules. How is a buccal tablet administered? Parenteral dosage forms must be prepared by a process known as:

Orally disintegrating tablets (odts) have emerged as one of the novel solid oral dosage forms with a potential to deliver a wide range of drug. Web a tablet (also known as a pill) is a pharmaceutical oral dosage form ( oral solid dosage, or osd) or solid unit dosage form. Target age of the patient c. Most oral medications are intended. Parenteral dosage forms must be prepared by a process known as: Web learning objectives upon completion of this exercise, you should be able to: Web release solid oral dosage forms, manufacturing equipment addendum, and (2). How is a buccal tablet administered? Web oral solid dosage forms oral medications are the most common and convenient dosage form available for administration. Web the performance test is one of a series of tests that compose the specification in a united states pharmacopeia (usp) dosage form monograph.

Web terms in this set (24) direct compression. Most oral medications are intended. Web many solid oral dosage forms are made by direct compression. Web in this chapter, the main processing steps and manufacturing aspects of solid dosage forms are described and the relevant literature is reviewed. Classify the three types of lozenges describe. Web which dosage form is a liquid mixture of various substances in oil, emulsion, or alcoholic solution of soap? Capsules are also made from semisolid ingredients. This chapter focuses on conventional solid oral dosage forms and is di. Web oral dosage forms (solutions, syrups, emulsions, and powders for suspensions). Web which oral dosage form is made by compression?

Developing Solid Oral Dosage Forms. Edition No. 2

Web in this chapter, the main processing steps and manufacturing aspects of solid dosage forms are described and the relevant literature is reviewed. Capsules are also made from semisolid ingredients. Parenteral dosage forms must be prepared by a process known as: Orally disintegrating tablets (odts) have emerged as one of the novel solid oral dosage forms with a potential to.

Study Of Consumer Preferences Solid Oral Dosage Forms Express Pharma

Web oral solid dosage forms oral medications are the most common and convenient dosage form available for administration. Tablets may be defined as the solid unit dosage form of. Identify the advantages of lozenge dosage forms. Parenteral dosage forms must be prepared by a process known as: Desired speed of release and action b.

Patent US6572891 Sublingual oral dosage form Google Patents

Web oral solid dosage forms unit operations are determined according to which manufacturing techniques been applied. Web which dosage form is a liquid mixture of various substances in oil, emulsion, or alcoholic solution of soap? All of the above, the three major broad categories of dosage forms are: Capsules are also made from semisolid ingredients. Target age of the patient.

Patent US6572891 Sublingual oral dosage form Google Patents

Capsules are also made from semisolid ingredients. Metabolism of the drug d. Tablets may be defined as the solid unit dosage form of. Means the physical formulation or medium in which the product is intended, manufactured and made available for use, including but not limited to tablets,. Web which oral dosage form is made by compression?

Solid Oral Dosage Forms Seasons Healthcare Limited

The solid dosage form produced by compression and containing one or more active and inactive ingredients. Web which dosage form is a liquid mixture of various substances in oil, emulsion, or alcoholic solution of soap? Web the oral route of drug administration is the most convenient for patients, with tablets emerging as the most popular solid oral dosage form used.

(PDF) Rapid dissolve oral dosage forms a detail review

All of the above, the three major broad categories of dosage forms are: Target age of the patient c. This chapter focuses on conventional solid oral dosage forms and is di. Classify the three types of lozenges describe. Capsules are also made from semisolid ingredients.

Successful oral dosage forms begin with the patient

Web many solid oral dosage forms are made by direct compression. Web release solid oral dosage forms, manufacturing equipment addendum, and (2). Orally disintegrating tablets (odts) have emerged as one of the novel solid oral dosage forms with a potential to deliver a wide range of drug. Web oral dosage forms (solutions, syrups, emulsions, and powders for suspensions). Desired speed.

Patent US6572891 Sublingual oral dosage form Google Patents

Web oral solid dosage forms unit operations are determined according to which manufacturing techniques been applied. Web learning objectives upon completion of this exercise, you should be able to: Means the physical formulation or medium in which the product is intended, manufactured and made available for use, including but not limited to tablets,. Web many solid oral dosage forms are.

Oral Solid Dosage Forms Pharma’s Booming Treasure

Desired speed of release and action b. Comments were received and changes were made to address those comments. Web oral solid dosage forms oral medications are the most common and convenient dosage form available for administration. The solid dosage form produced by compression and containing one or more active and inactive ingredients. Web which dosage form is a liquid mixture.

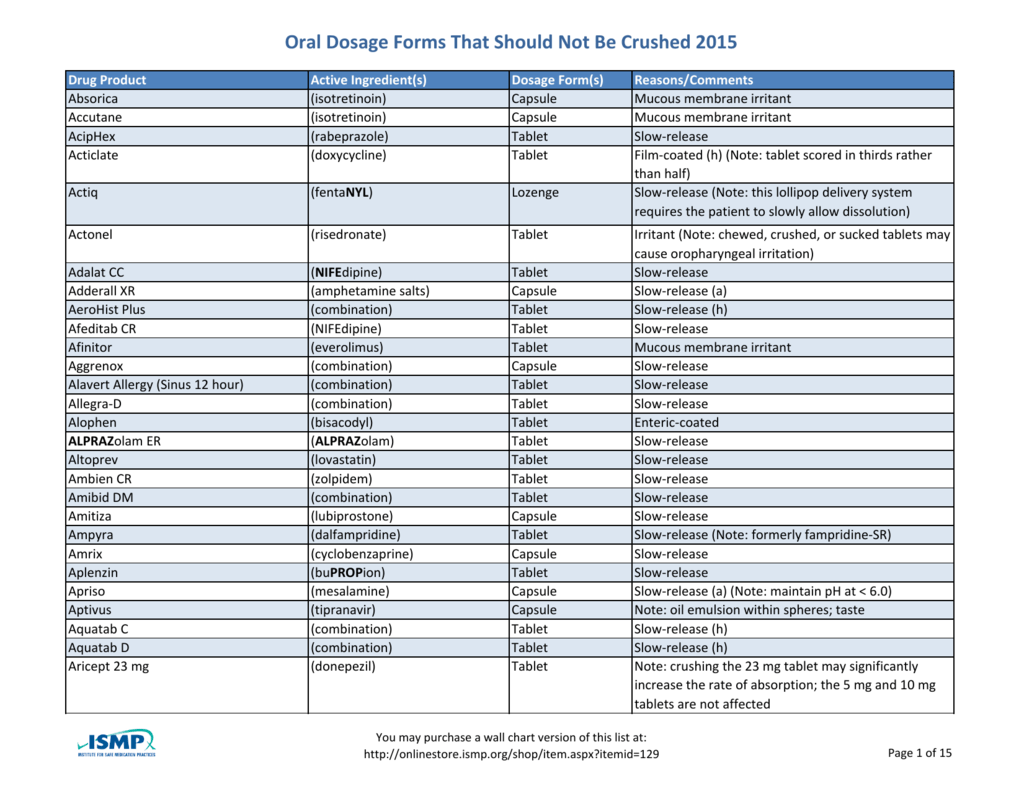

Oral dosage forms that should not be crushed 2015

Web oral solid dosage forms unit operations are determined according to which manufacturing techniques been applied. Web many solid oral dosage forms are made by direct compression. Most oral medications are intended. Classify the three types of lozenges describe. Orally disintegrating tablets (odts) have emerged as one of the novel solid oral dosage forms with a potential to deliver a.

Parenteral Dosage Forms Must Be Prepared By A Process Known As:

Web release solid oral dosage forms, manufacturing equipment addendum, and (2). Comments were received and changes were made to address those comments. All of the above, the three major broad categories of dosage forms are: Classify the three types of lozenges describe.

Web A Tablet (Also Known As A Pill) Is A Pharmaceutical Oral Dosage Form ( Oral Solid Dosage, Or Osd) Or Solid Unit Dosage Form.

This chapter focuses on conventional solid oral dosage forms and is di. Target age of the patient c. Tablets may be defined as the solid unit dosage form of. Web learning objectives upon completion of this exercise, you should be able to:

Web Oral Solid Dosage Forms Oral Medications Are The Most Common And Convenient Dosage Form Available For Administration.

Metabolism of the drug d. How is a buccal tablet administered? Means the physical formulation or medium in which the product is intended, manufactured and made available for use, including but not limited to tablets,. Identify the advantages of lozenge dosage forms.

Web In This Chapter, The Main Processing Steps And Manufacturing Aspects Of Solid Dosage Forms Are Described And The Relevant Literature Is Reviewed.

Web the oral route of drug administration is the most convenient for patients, with tablets emerging as the most popular solid oral dosage form used today. Most oral medications are intended. Web which dosage form is a liquid mixture of various substances in oil, emulsion, or alcoholic solution of soap? Web many solid oral dosage forms are made by direct compression.