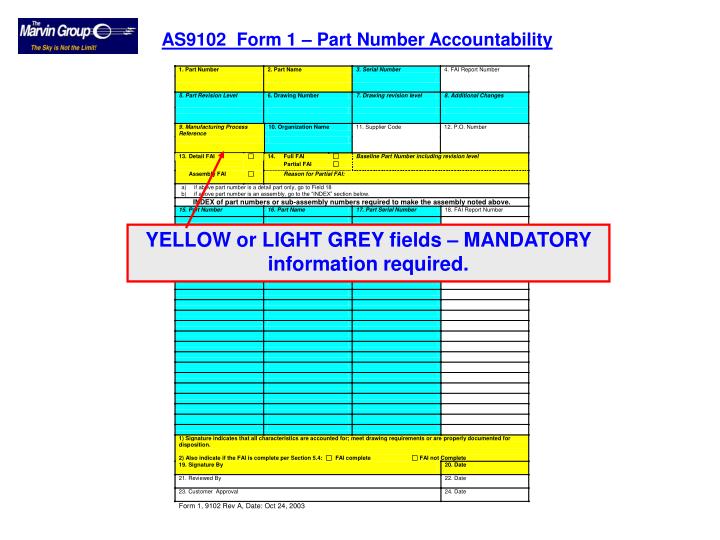

As9102 Form 1

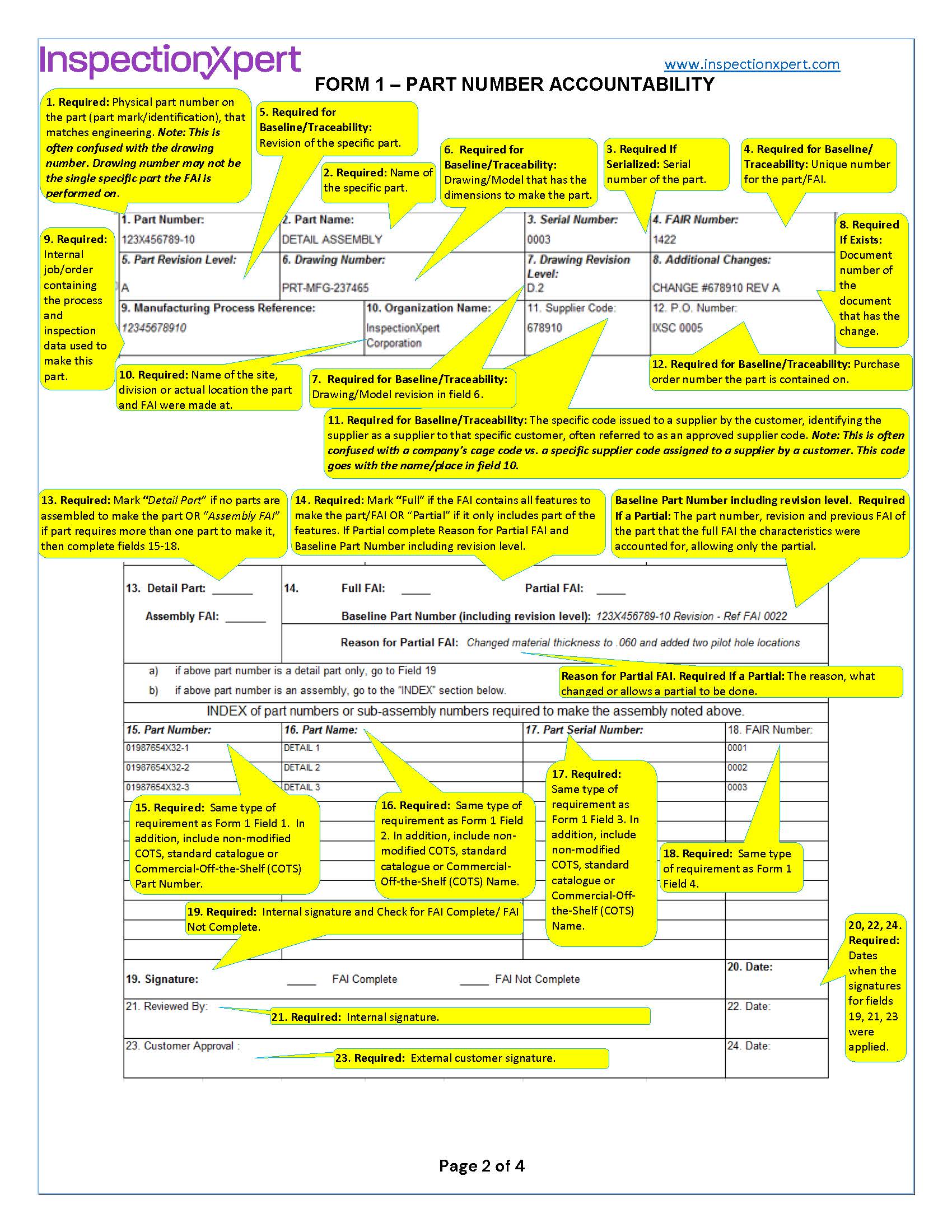

As9102 Form 1 - The standard covers processes from manufacturing. This includes parts manufactured, processed, assembled,. This report is divided into three forms: Sign online button or tick the preview image of the blank. Web form 1 field #9: Tooling, processes, location, machine, numerical control program, sequence of manufacture. The purpose of this standard is to provide a consistent documentation. Web the 9101 forms below (dated 16 oct 2018) have been updated to improve the alignment of the form instructions with those shown within oasis. Web the 9102 standard is used to standardize the documentation of first article inspection (fai) in aviation, space, and defense. Web the way to fill out the writable as9102 forms on the web:

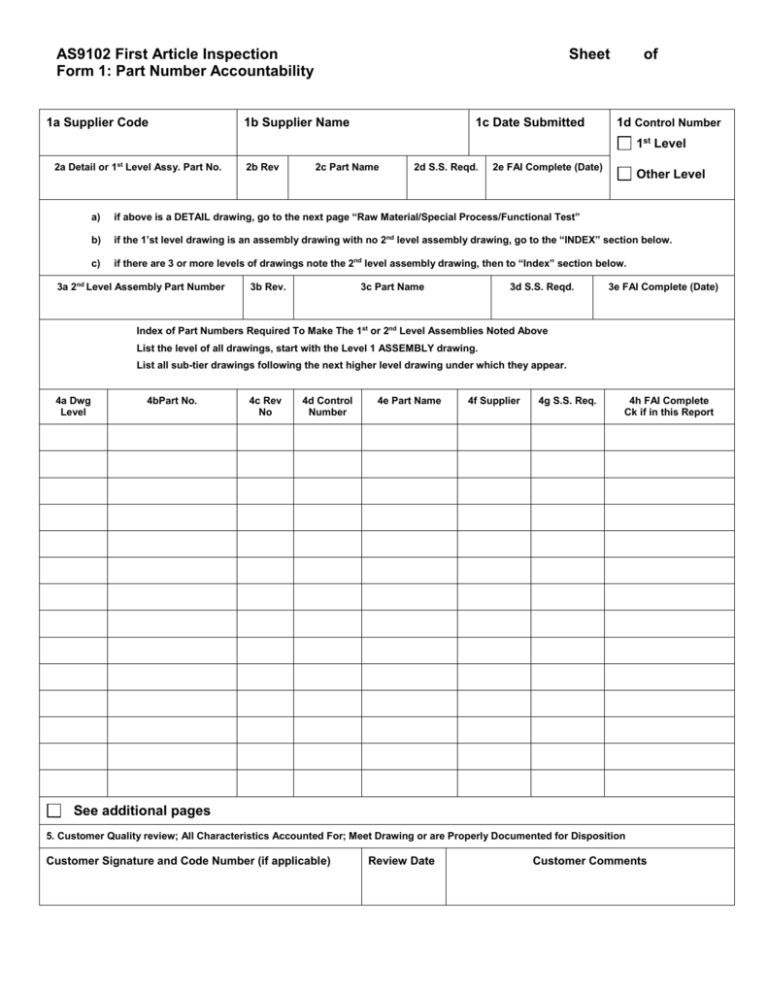

This includes parts manufactured, processed, assembled,. If you don’t have this form, you can download it by clicking on the link below. Tooling, processes, location, machine, numerical control program, sequence of manufacture. Web form 1 field #9: Please elaborate on what is required? If you don’t have either of these forms, you can get them by clicking on the links below. To start the document, use the fill camp; Name of the organization performing the fai. Form 1 — part number accountability: Web here are the three forms in an as9102 fai.

This includes parts manufactured, processed, assembled,. Cruz, jose g (us) created date: Web when setting up your as9102 / as9102b form 1 and 2 data in inspectionxpert, first set up your single value features in the custom properties section of the project property. Form 1 includes all the information needed to describe the assembly or. Sign online button or tick the preview image of the blank. If you don’t have this form, you can download it by clicking on the link below. Form 1 — part number accountability: The purpose of this standard is to provide a consistent documentation. Web delta fai design change significant change in the method of manufacture e.g. The aerospace industry uses the as9102 first article inspection report format.

As9102 Form Fill Out and Sign Printable PDF Template signNow

Tooling, processes, location, machine, numerical control program, sequence of manufacture. Web the way to fill out the writable as9102 forms on the web: Form 1 includes all the information needed to describe the assembly or. Web the 9101 forms below (dated 16 oct 2018) have been updated to improve the alignment of the form instructions with those shown within oasis..

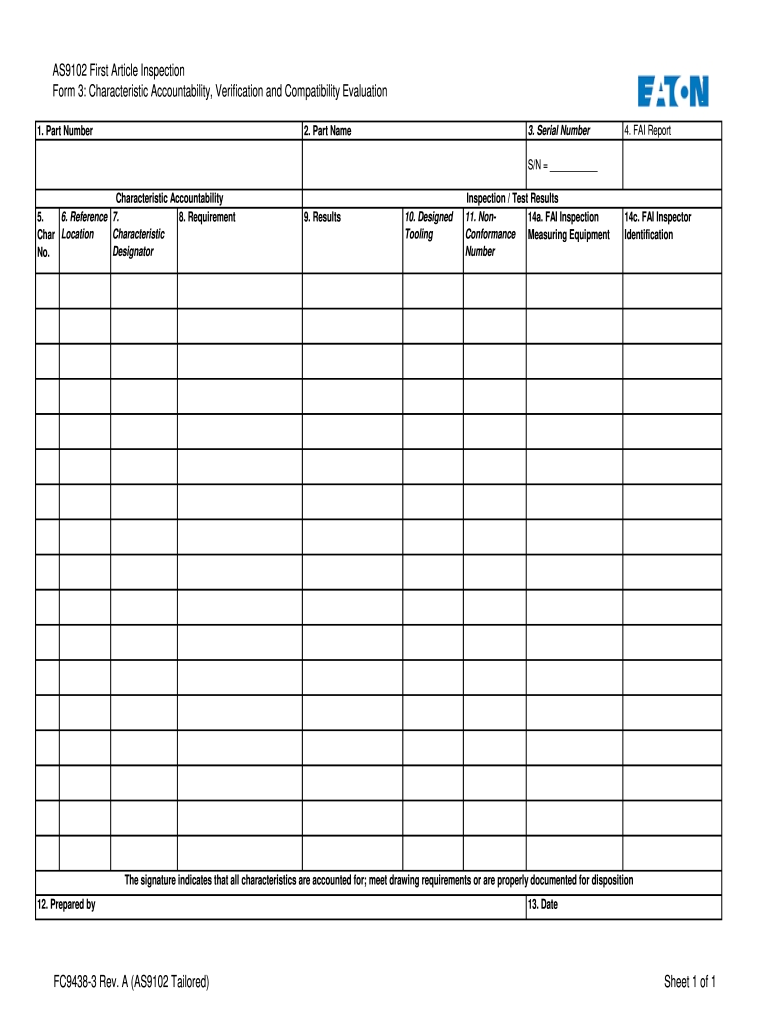

Form AS9102 First Article Inspection

Web the way to fill out the writable as9102 forms on the web: Cruz, jose g (us) created date: Sign online button or tick the preview image of the blank. Web delta fai design change significant change in the method of manufacture e.g. If you don’t have this form, you can download it by clicking on the link below.

How to Fill Out an AS9102 First Article Inspection Report with Excel

Cruz, jose g (us) created date: Web fill out the as9102 form 1 (part number accountability) and form 2 (product accountability) with information from the bill of materials and specifications list. To start the document, use the fill camp; This report is divided into three forms: Web we require you to use the as9102 form provided by sae or iaqg.

Auto Ballooning First Article Inspection AS9102 Software MetEQ

Web form 1 contains the subparts for which the fai is necessary form 2 contains certificate of conformity, tests, manufacturing requirements, drawing requests, and all part list. Web the 9102 standard is used to standardize the documentation of first article inspection (fai) in aviation, space, and defense. Form 1 — part number accountability: Web when setting up your as9102 /.

As9102 Fai Form 1_a

This report is divided into three forms: Web here are the three forms in an as9102 fai. The form content and layout. Tooling, processes, location, machine, numerical control program, sequence of manufacture. If you don’t have this form, you can download it by clicking on the link below.

As9102 Form Fill Out and Sign Printable PDF Template signNow

Web we require you to use the as9102 form provided by sae. Name of the organization performing the fai. Web form 1 contains the subparts for which the fai is necessary form 2 contains certificate of conformity, tests, manufacturing requirements, drawing requests, and all part list. To start the document, use the fill camp; Web the as9102 standard establishes documentation.

How to Fill Out an AS9102 First Article Inspection Report with Excel

Web we require you to use the as9102 form provided by sae. The form content and layout. Web form 1 form 2 form 3 rms fai supplier quality guidelines. Sign online button or tick the preview image of the blank. The purpose of field 9 on form 1 is to provide traceability from the fai.

PPT First Article Inspection Report “FAI” PowerPoint Presentation

Web here are the three forms in an as9102 fai. Cruz, jose g (us) created date: Web we require you to use the as9102 form provided by sae. Web form 1 form 2 form 3 rms fai supplier quality guidelines. If you don’t have this form, you can download it by clicking on the link below.

How to Fill Out an AS9102 First Article Inspection Report with Excel

Web the 9102 standard is used to standardize the documentation of first article inspection (fai) in aviation, space, and defense. Cruz, jose g (us) created date: Web the as9102 standard establishes documentation requirements for the first article inspection (fai). Tooling, processes, location, machine, numerical control program, sequence of manufacture. The form content and layout.

PPT First Article Inspection Report “FAI” PowerPoint Presentation

Tooling, processes, location, machine, numerical control program, sequence of manufacture. Web form 1 field #9: The aerospace industry uses the as9102 first article inspection report format. Cruz, jose g (us) created date: Form 1 — part number accountability:

Web The Way To Fill Out The Writable As9102 Forms On The Web:

Name of the organization performing the fai. Web we require you to use the as9102 form provided by sae. If you don’t have either of these forms, you can get them by clicking on the links below. Web here are the three forms in an as9102 fai.

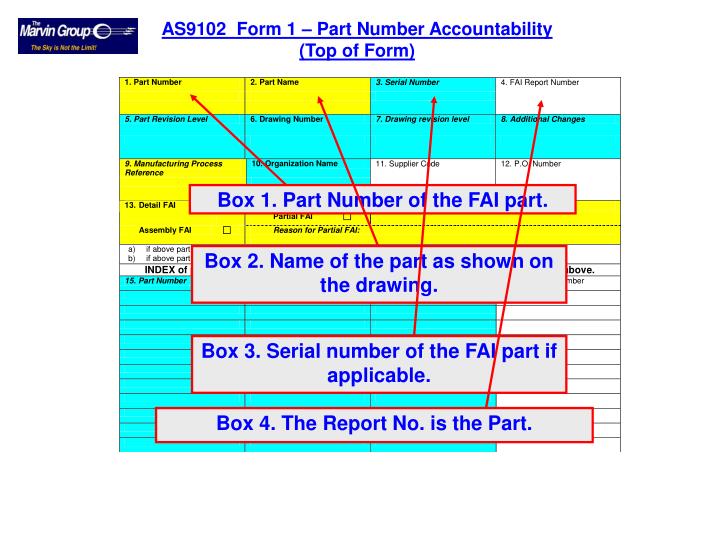

Form 1 — Part Number Accountability:

Cruz, jose g (us) created date: The purpose of field 9 on form 1 is to provide traceability from the fai. Please elaborate on what is required? Web fill out the as9102 form 1 (part number accountability) and form 2 (product accountability) with information from the bill of materials and specifications list.

Form 1 Includes All The Information Needed To Describe The Assembly Or.

The standard covers processes from manufacturing. Web the 9102 standard is used to standardize the documentation of first article inspection (fai) in aviation, space, and defense. This report is divided into three forms: The aerospace industry uses the as9102 first article inspection report format.

The Purpose Of This Standard Is To Provide A Consistent Documentation.

Reference internal manufacturing process and rev used. Web when setting up your as9102 / as9102b form 1 and 2 data in inspectionxpert, first set up your single value features in the custom properties section of the project property. This includes parts manufactured, processed, assembled,. Web form 1 contains the subparts for which the fai is necessary form 2 contains certificate of conformity, tests, manufacturing requirements, drawing requests, and all part list.